DoorCRUNCHER | Professional Cabinet Door Cutlist Calculator

Eliminate Errors and Build Perfectly Fitted Cabinet Doors Every Time with DoorCRUNCHER

The fastest way to calculate custom door and drawer front sizes. Simply enter your opening dimensions and overlay specs to get an instant, error-free cut list for every part. Handle complex inset or overlay projects with total confidence.

Whether you are a professional shop owner looking to maximize profitability or a woodworking enthusiast building your next cabinet project, the most time-consuming part of any build is the math. A single 1/16" error on a rail or stile can lead to wasted material and hours of rework.

DoorCRUNCHER is a powerful, Excel-based calculator designed to eliminate mathematical errors. In just minutes, you can generate a complete, professional cutting list for your entire project. DoorCRUNCHER is fully adjustable, allowing you to create accurate cut lists for most door or drawer front construction styles using the shop standards and joinery methods you already use.

Getting Started with Door-DrawerCRUNCHER

DoorCRUNCHER and DrawerCRUNCHER are bundled together in the same application called Door-DrawerCRUNCHER.

Engineered for the Pro Shop - Simplified for the Enthusiast

Why Professionals & Woodworkers Choose DoorCRUNCHER

- Universal Compatibility: Works for all common construction methods, including cope and stick joinery, mitered frame, mortise and tenon joinery, or pocket-holes.

- Fully Customizable: Easily set your own rail and stile dimensions with widths, panel groove depths, and overlays or insets.

- Instant Material Lists: Automatically calculates the exact quantity of hardwood and panel materials required for your project.

- Fractional or Metric: Switch seamlessly between formats to match your shop’s preference.

- The Power of Excel: DoorCRUNCHER is an Excel-Based Woodworking Software offering a streamlined interface that is incredibly easy to learn and use.

Streamline Your Production with DoorCRUNCHER's Project Estimating and Cutlist Tools

- High-Volume Batching: Itemize and "crunch" hundreds of doors and drawer fronts simultaneously to save hours of office prep time.

- Seamless Integration: Save time by copying itemized lists directly from CabinetCRUNCHER into the DoorCRUNCHER module.

- Precision Costing: Protect your margins with automated Average Cost per Sq Ft and Total Project Cost calculations that include labor and overhead.

- Lumber Yield Optimization: Get instant Lineal Ft and Rip Qty requirements based on your specific stock lengths (e.g., 10ft or 12ft boards) to streamline your ordering.

Master Every Detail with Precision Joinery and Intelligent Material Tracking

- Error-Free Joinery: Visual diagrams guide you through setting Tenon Lengths and Dado Depths so your cope-and-stick joints fit perfectly the first time.

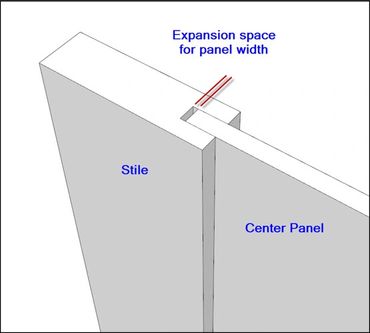

- Adjustable Expansion Gaps: Allow for wood movement by adjusting the expansion space for center panels

- Fractional (or Metric) Accuracy: All cutlists are generated in either standard shop fractions, millimeters, or decimals.

- Smart Material Lists: Know exactly how many Board Feet of hardwood and how many Sheets of plywood to buy before you head to the lumber yard.

Two Methods to Generate Your Cut List

Method 1: Build by Finished Door Size

DoorCRUNCHER offers the flexibility to work exactly how you do. Whether you are building brand-new custom cabinetry or performing a high-profit kitchen refacing, you can generate a precision cut list in minutes.

Method 1: Build by Finished Door Size

Best for when you have already calculated your final door dimensions or are replicating an existing set of fronts. DoorCRUNCHER uses a unique "Door Group" system to keep your project organized:

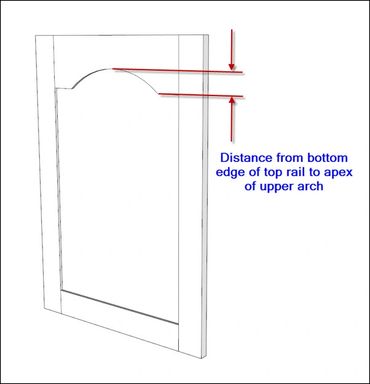

- Group Management: Separate your project into up to three distinct construction groups (e.g., Group 1 for Cathedral Uppers, Group 2 for Shaker Lowers).

- Independent Specs: Each group maintains its own joinery and styling requirements, ensuring that complex, multi-style projects remain error-free.

- CabinetCRUNCHER Integration: For maximum workflow efficiency, you can import your itemized door and drawer front list directly from CabinetCRUNCHER via copy-and-paste to auto-populate your Door Groups.

Method 2: Build by Cabinet Opening Size (Perfect for Refacing)

This is the way to go for cabinet refacing projects, or if you need to calculate the door sizes based on the cabinet opening sizes. If you are keeping the existing cabinet boxes and just updating the look, this method is fast and easy.

- Automated Overlay & Reveal Logic: Define your desired side, top, and bottom overlays (e.g., 1/2" or 1-1/4"). The software automatically calculates the final door dimensions based on these technical offsets.

- Split-Door Calculations: For double-door openings, simply input the single opening width; DoorCRUNCHER automatically calculates the width for double doors, allowing for a user-defined center reveal (e.g., 1/16" or 1/8") to ensure a perfect fit.

- Dynamic Sizing: As you adjust your overlay or gap settings, the entire cutlist updates in real-time, ensuring that all rails, stiles, and panels reflect the new dimensions instantly.

- Instant Kitchen Refresh: The program automatically calculates the new door sizes and corresponding cutlists. It’s the fastest way to "crunch" an entire kitchen refacing job from a simple set of site measurements.

- Modernize Any Style: Easily update dated cabinets to modern Slim-line Shaker or Slab styles by adjusting rail and stile widths to match today's trends.

Adjust Cut List Settings

DoorCRUNCHER includes a wide variety of overlay and inset doors, drawer fronts and end panel configurations. You can customize these configurations to almost any construction specification for your woodworking project. For each door/panel, you will select from the following construction types:

- Cope and Stick

- Mitered

- 2-Panel (Horizontal Center Rail)

- 2-Panel (Vertical Center Stile/Mullion)

- 3-Panel

- 4-Panel

- Solid Panel

Within each door/panel type, you can adapt the configurations to support many different styles. For example, by adjusting the width of the stiles and rails of a “Cope & Stick” configuration, you can create any of the following styles of flat or raised panel doors:

- Raised panel doors

- Shaker style doors

- Cathedral style doors

- Curved Top doors

- Curved Top & Bottom doors

For professional results, DoorCRUNCHER includes an optional "Allow for Trim after Glue-Up" function. This feature ensures your finished doors are perfectly square and have clean, glue-free edges.

- Precision Squaring: By adding a small amount of "extra meat" to the stiles and rails, you can trim the assembled door to its exact final dimension after the glue-up assembly is dry.

- How it Works: Simply enter your desired trim allowance (e.g., 1/8" on each side). If your finished door size is 24" x 36", DoorCRUNCHER will automatically calculate a "rough" assembly size of 24.25" x 36.25".

- The Result: After trimming 1/8" off each of the four edges, you are left with a perfectly square, 24" x 36" door with crisp, factory-clean edges.

Door Software Calculates Bill of Materials & Estimates Project Costs

Your cutlist and materials will be automatically generated on the Project Summary sheet with the following information:

- Project Information (project name and project number)

- Panel Quantity This section summarizes the quantity of all doors, false doors, drawer fronts, false drawer fronts and applied end panels for your entire project. This information is generated automatically based on the information in “Group 1”, “Group 2”, “Group 3”, and “Cabinet Opening Requirement” worksheets.

- Production (Rip Length) Quantity This section summarizes the total lineal length of each width of stile and rail used on your project. This information is intended to help you plan the quantity of “rip lengths”. EXAMPLE: If the total "lineal feet" for a particular material is 50, and your rip length is set to 10, you will need to cut 5 strips of material at 10 feet long.

- List of Materials - summarizes the type and quantity of all materials used on your project.

- Project Cost - Summarizes the total material cost, and provides optional criteria for you to establish other costs associated with the project such as production labor, finishing, delivery, installation, etc. You can change the cost item descriptions and their associated costs based on your preferences.

- Notes (optional)

Precise Door Cutting List for Your Entire Project in Minutes

Master Project Cut List: Your Production Command Center

This section automatically compiles every component from your entire project—including doors, drawer fronts, and end panels—into one comprehensive master list. By aggregating data from all your Door Groups and Cabinet Opening worksheets, DoorCRUNCHER provides a bird's-eye view of your total material needs.

Smart Filtering for Efficient Manufacturing

Don’t just read a list—organize your workflow. Use Excel's built-in filters to transform the way you build:

- Batch Processing: Filter for Stiles and Rails only, then sort by Width. This allows you to set your table saw fence once and "rip" every structural component in the project at the same time, significantly reducing setup time and errors.

- Sequential Cutting: Sort by Length to streamline your cross-cutting at the miter saw, ensuring you process your longest boards first to maximize material yield.

- Material Grouping: Instantly isolate parts by material type (e.g., solid wood vs. MDF) to organize your shop floor by station.

- Custom Shop Checklists: Use filters to create specific checklists for assembly, sanding, or finishing, ensuring no part of a complex kitchen project is ever left behind.

Software to Build Your Doors Correctly - the 1st Time!

Comprehensive Features & Construction Capabilities

Build a Wide Variety of Cabinet Doors, Drawer Fronts, and End Panels

- Easily generate a cabinet door cutlist for any flat or raised panel project.

- Universal Joinery: Support for cope and stick (tenon) or mitered construction methods.

- Pro-Level Versatility: Coordinate custom combinations of doors, drawer fronts, and end panels for a unified shop project.

Supports All Industry-Standard Construction Techniques

- DoorCRUNCHER is compatible with your existing shop standards and router bit sets.

- Custom Joinery: Works with any routed or mitered rail and stile dimensions.

- Material Flexibility: Design using solid wood, MDF panels, glass, or metal inserts.

Precision Cut List Calculator & Customization

- Take total control over your project math without the steep learning curve of CAD.

- Automated Sizing: Calculate exact part dimensions based on your cabinet opening sizes.

- Total Shop Control: Set independent rail and stile widths and adjust dado depths for a perfect panel fit.

- Expansion Gaps: Fine-tune center panel tolerances to allow for natural wood movement.

- Supports Imperial (Fractional) and Metric (millimeter) units.

Comprehensive Material Calculation & Project Requirements

- Stop guessing your costs. Get an automated board footage calculator and shopping list instantly.

- Waste Reduction: Generates sheet stock quantities and lineal footage requirements.

- Production Ready: Provides exact "Rip Lengths" for rails and stiles to speed up your cabinet shop workflow.

The Power of Excel-Based Woodworking Software

- Skip the complex design programs. DoorCRUNCHER provides a fast, intuitive, spreadsheet-based interface.

- No CAD Required: If you can use a spreadsheet, you can generate professional cut lists in minutes.

- Streamlined Workflow: Simple data entry with on-screen guidance designed for both professional shops and DIYers.

Perfect Door & Panel Cutlists: Get it Right the First Time

From Estimate to Invoice: Professional Project Costing

Stop Guessing, Start Profiting: Your Total Project Management Dashboard

DoorCRUNCHER is more than a calculator; it is a complete Project Management Dashboard. Instead of guessing your margins, you can instantly see the financial health of your project before you ever make the first cut.

- Automated Material Costing: Instantly calculate costs for both solid materials (Board Feet) and sheet goods (Sheets) based on real-time project dimensions.

- Labor & Overhead Tracking: Factor in production labor by hour and rate, alongside additional expenses like hardware, finishing, and installation.

- Precision Bidding: Use the Average Cost per Sq Ft metric to ensure your quotes are consistent, competitive, and profitable.

- Accurate Lumber Ordering: Eliminate waste and "extra trips" with calculated Lineal Footage and Rip Quantities based on your specific stock lengths.

- Total Project Transparency: See your total project cost at a glance, allowing for instant adjustments to labor or material rates to meet a client's budget.

The 3-Step Guide to Profitable Quoting

One of the biggest challenges for small shops and DIYers is "hidden costs." DoorCRUNCHER eliminates the guesswork by providing a real-time financial breakdown of your project.

1. Automated Material Quantities

Stop manual board-foot calculations. Once your door sizes are entered, the dashboard instantly provides:

- Lumber Requirements: Exact board footage for solid wood (e.g., Cherry) and sheet counts for panels.

- Specific Rip Lists: It tells you exactly how many lineal feet you need and how many physical boards (Rip Qty) to buy based on your stock length (e.g., 10-foot boards).

2. Comprehensive Labor & Overhead

A profitable job must account for time. The dashboard allows you to:

- Calculate Labor: Enter your hourly rate and the estimated hours to see a total production labor cost (e.g., 24 hours at $50/hr).

- Factor in Extras: Add line items for hardware, delivery, finishing, and installation so you never undercharge for the "small things".

3. Real-Time Margin Analysis

Before you send the quote, verify your numbers with the Project Totals:

- Total Project Cost: See the bottom line immediately (e.g., $1,544.06).

- Average Cost per Sq Ft: This is your most powerful metric. Use the calculated square-foot cost (e.g., $29.75) to quickly compare this job to previous projects and ensure your pricing is consistent.

The DoorCRUNCHER Profitability Checklist

One of the biggest challenges for small shops and DIYers is "hidden costs." DoorCRUNCHER eliminates the guesswork by providing a real-time financial breakdown of your project.

1. Material Precision

- Verify Waste Percentage: Did you add a 10-15% buffer to the Board Footage to account for knots, grain matching, or shop errors?

- Sheet Good Yield: If the dashboard shows 1.1 sheets, ensure you have quoted for 2 full sheets, as most suppliers won't sell partial panels.

- Current Market Pricing: Check the Cost column against today’s lumber prices for your species (e.g., Cherry) to ensure your "Adjust Material Cost" is accurate.

2. Labor & Production

- Prep & Cleanup: Does your Production Labor quantity include time for setting up the router table, cleaning up glue squeeze-out, and final sanding?

- Finishing Time: If you are finishing the doors in-house, ensure the Finishing line item covers both the material (stain/topcoat) and the spray time.

3. The "Hidden" Costs

- Hardware Check: Did you include the cost of hinges, pulls, or drawer slides in the Hardware field?

- Delivery & Install: If you are doing the install, factor in travel time and site supplies (screws, bumpers, shims) under Installation.

4. Workflow Optimization

- Rip Quantity Check: Review the Rip Qty to see if you have enough physical boards on hand to complete all the stiles and rails in a single production run.

- Batching Strategy: Look at your Lineal Ft requirement; can you combine these cuts with another project to further reduce your waste?

5. Final Margin Audit

- The "Sanity Check": Compare your Average Cost per Sq Ft to your shop's standard minimum. If your calculated cost of $29.75 is lower than your target, adjust your labor rate or material markup accordingly.

Frequently Asked Questions

Please check the Frequently Asked Questions on each of the product pages. If you cannot find an answer to your question, please contact us at sales@cabinetcruncher.com, or phone 206-818-0109.

No. DoorCRUNCHER is bundled together with DrawerCRUNCHER. To provide a complete solution for your cabinetry needs, both tools are combined into a single, powerful software package known as Door-DrawerCRUNCHER. This allows you to manage every front-facing element of your project—from the doors to the drawer boxes and fronts—within one unified system.

Yes. Door-DrawerCRUNCHER can be purchased as a separate, standalone software module for those specifically focused on door and drawer production. However, it is most commonly delivered as a core component of the CabinetCRUNCHER suite (refer to Package 1 through Package 6).

Yes. CabinetCRUNCHER itemizes every door and drawer front required for your project into a standardized list. This data can then be copied and pasted directly into the Door-DrawerCRUNCHER module for immediate processing of final cut lists, joinery specifications, and material yield totals. Once your list is pasted, simply adjust your Cutlist Settings (like tenon lengths and panel gaps), and the program will automatically calculate every component for all of your project's doors instantly.

Not at all. DoorCRUNCHER is designed with an automated "point-and-click" methodology. We have done the heavy lifting with complex formulas and logic; all you have to do is enter your settings into the clearly highlighted fields. If you can enter a number into a cell, you can generate a professional cut list very easily.

Please refer to System Requirements

Yes. Whether you are building traditional 1/2" or 1-1/4" overlays or sophisticated flush inset doors, DoorCRUNCHER handles the math. Simply select your style in the "Cabinet Openings" worksheet, and the software automatically calculates the necessary gaps and finished door dimensions.

Absolutely. Unlike rigid, basic calculators, DoorCRUNCHER allows for independent rail and stile adjustments. This is perfect for creating modern "Weighted Bottom" rails or custom "Slim-line" Shaker designs where the stiles might be narrower than the rails.

Yes. Within the Cut List Settings, you can specify exact expansion spaces for both panel width and height (e.g., 1/8") to prevent cracking or rattling. The software automatically deducts these tolerances from the final panel cut list.

This is a favorite for pro shops and experienced woodworkers. If enabled, the software adds a small "trim allowance" (e.g., 1/8") to your rail and stile widths. This allows you to assemble the door slightly oversized so you can clean up glue-lines and perfectly square the door on your table saw or sliding cross-cut saw after the glue has set.

Yes. Our unique "Door Group" system allows you to categorize your project into three distinct sections. You can calculate Arched Cathedral uppers in Group 1, Standard Cope & Stick lowers in Group 2, and Slab drawer fronts in Group 3 - all while generating one master material list.

By providing an instant calculation of Total Board Footage and Lineal Footage, you know exactly how much material to order from your supplier. This prevents expensive "extra trips" to the lumber yard and minimizes waste by allowing you to plan your rips more efficiently.

Yes. The Master Cut List can be sorted and filtered based on your production needs. Most users filter by Part Type (Stiles/Rails) and sort by Width. This lets you rip all components of the same width in one batch, meaning you set your table saw fence once and process the entire kitchen's worth of parts in minutes.

DoorCRUNCHER features a built-in Project Costing section. By entering your material costs and labor rates, the dashboard automatically generates a Total Project Cost and an Average Cost per Sq Ft, ensuring you never leave money on the table.

You can generate a complete cut list and material summary for 50+ doors in just minutes. DoorCRUNCHER is designed for high-speed processing, allowing you to "crunch" an entire project's worth of data all at once rather than calculating doors one by one.

Copyright © 2026 CabinetCRUNCHER Cabinet Design & Construction Software. All Rights Reserved.