DrawerCRUNCHER | Cabinet Drawer Box & Tray Cut List Software

The Simple, Affordable Way to Create Precision Cut Lists for Cabinet Drawer Boxes and Roll-out Trays Using Any Construction Method

Properly fitted drawers and slide-out trays are critical to the success of any cabinetry or furniture project. To ensure seamless operation, precise hardware clearances and exact component measurements are essential.

Whether you are crafting a custom kitchen, a bathroom vanity, or a single piece of fine furniture, DrawerCRUNCHER provides the technical precision needed for a perfect fit. This easy-to-use tool eliminates "math fatigue" and manual calculation errors, providing accurate material lists and cost breakdowns in one intuitive interface.

DrawerCRUNCHER ensures precise cut list calculations and saves valuable time and materials. Get accurate material requirements and a project cost summary, all in one easy-to-use tool. Perfect for professional cabinet makers, woodworkers, and DIY enthusiasts.

Getting Started with Door-DrawerCRUNCHER

DrawerCRUNCHER and DoorCRUNCHER are bundled together in the same application called Door-DrawerCRUNCHER.

Save Time & Eliminate Costly Mistakes!

Precision for the Pro Shop - Simplicity for the Enthusiast

Professional Results Made Simple: Why Woodworkers Choose DrawerCRUNCHER

Built for Your Shop: Flexible Joinery & Effortless Operation

DrawerCRUNCHER adapts to your signature building style, allowing you to maintain your craftsmanship while the software handles the tedious math. Whether you are building high-end dovetailed boxes or utility-grade shop trays, the process is simple, fast, and highly customizable.

Supports All Industry-Standard Methods:

- Traditional Joinery: Effortlessly calculate offsets for Through Dovetails, Half-Blind Dovetails, and Box Joints.

- Shop-Standard Construction: Quickly generate lists for Dado and Rabbet joints, Locking Miters, or simple Butt-Joint assembly.

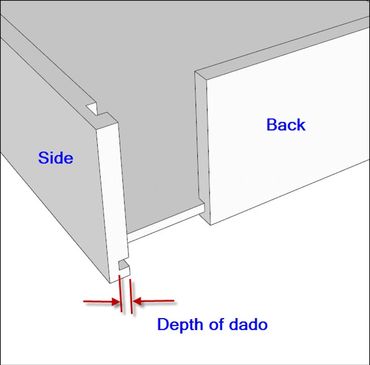

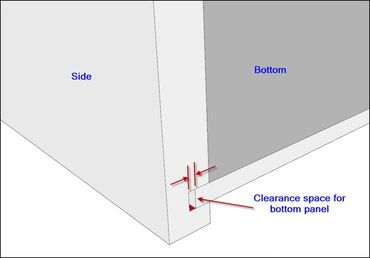

- Customizable Bottoms: Define your specific dado depth and required "rattle room" expansion clearance; the software automatically calculates the final panel size.

- Total Material Control: Use any thickness or species. Mix and match materials—like solid maple sides with pre-finished birch bottoms—to suit your project needs.

Easy to Learn, Even Easier to Use:

- No Steep Learning Curve: There are no complex CAD menus to navigate. If you can enter a number into a spreadsheet cell, you can use DrawerCRUNCHER.

- Highlighted Data Entry: Simply fill in the clear, color-coded fields. The software "crunches" the numbers and updates your entire project list and material costs instantly.

- Helpful On-Screen Guidance: Technical comments and diagrams are built right into the spreadsheet to guide you through hardware clearances and joinery settings as you work.

The 3-Step Workflow: From Dimensions to Production

The DrawerCRUNCHER workflow is identical to DoorCRUNCHER—designed to be simple, fast, and repeatable.

- Step 1: Enter Your Box Sizes - Simply enter (or copy and paste from CabinetCRUNCHER) your finished box dimensions and quantities. The software instantly applies your joinery and material offsets to every item on the list.

- Step 2: Define Your Shop Standards - Enter your preferred construction settings. Select your joinery type (dovetails, dadoes, etc.), material thicknesses, and bottom panel clearances. These settings become your global "shop standard" for the entire project.

- Step 3: Print Your Production Reports - DrawerCRUNCHER automatically generates a clean, fractional or metric cut list for the shop floor, a master material list for procurement, and a detailed cost estimate to keep your project on budget.

Adjusting Cut List Settings

DrawerCRUNCHER includes a wide variety of construction configurations for drawer boxes and roll-out trays. You can customize these configurations to almost any construction specification or hardware requirement for your woodworking project. For each drawer or tray, you will select from the following industry-standard joinery types:

- Through Dovetail Joints

- Half-Blind Dovetail Joints

- Dado or Rabbet Construction

- Locking Miter Joints

- Box Joints

- Butt-Joints (Pocket Hole construction or mechanical fasteners)

Within each joinery type, you can adapt the configurations to support many different building styles and hardware clearances. For example, by adjusting the component offsets and dado depths, you can create professional results for any of the following applications:

- Standard Drawer Boxes (any depth or height)

- Under-mount Slide Drawers (with specific bottom clearances)

- Side-mount Slide Drawers (with precise side-clearance logic)

- Roll-out Trays / Pull-outs (with low-profile or scooped fronts)

- File Drawers and Specialized Storage

- Shop Utility Trays

Drawer Software Calculates Bill of Materials & Estimates Project Costs

Following the same format as DoorCRUNCHER, your professional cut list and material requirements are automatically generated on the Project Summary sheet, providing a comprehensive overview of your entire project:

- Project Information: Displays your specific project name and project number for easy filing and shop organization.

- Drawer & Tray Quantity: This section summarizes the total count of all drawer boxes and roll-out trays (slide-outs) for your entire project. This data is updated automatically based on the specifications entered in your worksheets.

- Production (Rip Length) Quantity: This section calculates the total lineal length for every width of side-panel material used. It is designed to help you prep your stock efficiently. Example: If your project requires 50 total lineal feet of 6” wide material, and your standard rip length is 10 feet, the software shows you need to prep 5 strips at that length.

- List of Materials: A complete summary of the type and quantity of all materials required, including lumber for drawer sides/fronts, sheet goods for bottom panels, and associated hardware.

- Project Cost: Summarizes your total material investment and includes customizable fields to track additional expenses such as production labor, finishing, hardware, and installation. You can easily modify these descriptions and costs to match your shop's pricing.

- Notes (Optional): A dedicated space for specific project instructions, assembly reminders, or client-specific details.

Precise Drawer Cutting List for Your Entire Project in Minutes

This section automatically compiles every component from your entire project—including all drawer boxes and slide-out trays—into one comprehensive master cut list. By aggregating data from each of the Drawer Build Groups, DrawerCRUNCHER provides a bird's-eye view of your total material needs.

Shop-Ready Organization for Efficient Manufacturing

Don’t just read a list—organize your workflow. Use Excel's built-in filters to transform the way you build:

- Batch Processing: Filter by Material Type and then sort by Width. This allows you to set your table saw fence once and "rip" every drawer side, front, and back in the project at the same time, significantly reducing setup time and errors.

- Sequential Cutting: Sort by Length to streamline your cross-cutting at the miter saw. This ensures you process your longest components first, allowing you to use the remaining off-cuts for smaller parts and maximize your material yield.

- Material Grouping: Instantly isolate parts by material type (e.g., solid maple for dovetail boxes vs. plywood for utility trays) to organize your shop floor by station and assembly priority.

- Precision Organization: Every part is clearly labeled by its parent unit, ensuring that as you cut, you can easily sort and stack components for efficient assembly.

Comprehensive Features & Construction Capabilities

Build a Wide Variety of Custom Drawer Boxes and Roll-Out Trays

Easily generate a precision drawer cut list for any cabinetry or furniture project.

- Universal Joinery Support: Choose from industry-standard construction methods, including Through or Half-Blind Dovetails, Dado, Rabbet, Box Joints, Locking Miters, or Butt-Joints.

- Pro-Level Versatility: Coordinate custom combinations of standard drawer boxes, high-back drawers, and low-profile roll-out trays for a unified shop project.

Supports All Industry-Standard Construction Techniques

DrawerCRUNCHER is designed to work with your preferred tools and existing shop standards.

- Hardware Compatibility: Easily adjust side and bottom clearances to match any slide manufacturer’s specifications, including side-mount ball-bearing or undermount slides like Blum Tandem.

- Material Flexibility: Design using any material thickness or type—perfect for solid wood dovetail boxes, birch plywood drawers, or utility-grade shop trays.

Precision Cut List Calculator & Customization

Take total control over your project math without the steep learning curve of complex CAD programs.

- Automated Sizing: Calculate exact component dimensions based on your finished box sizes or your cabinet opening dimensions.

- Total Shop Control: Set independent dimensions for fronts, backs, and sides, and adjust dado depths and bottom panel "rattle room" for a perfect fit every time.

- Joinery Offsets: The software automatically calculates the necessary part-length adjustments based on your specific joinery choice.

- Multi-Format Support: Works seamlessly in Imperial (Fractional 1/16"), Metric (millimeter), or Decimal units.

Comprehensive Material Calculation & Project Requirements

Stop guessing your material costs. Get an automated board footage calculator and detailed shopping list instantly.

- Waste Reduction: Automatically generates sheet stock quantities for drawer bottoms and total board footage or lineal footage for the box sides.

- Production Ready: Provides an itemized list of every component required for your project, making it easy to organize your workflow at the saw.

The Power of Excel-Based Woodworking Software

Skip the complex design programs. DrawerCRUNCHER provides a fast, intuitive, spreadsheet-based interface.

- No CAD Required: If you can use a spreadsheet, you can generate professional cut lists in minutes.

- Streamlined Workflow: Simple data entry with on-screen guidance designed specifically for the needs of small cabinet shops, independent woodworkers, and DIYers.

- Seamless Integration: Bundled with DoorCRUNCHER in the same application, allowing you to manage all door and drawer production in one central file.

From Estimate to Invoice: Professional Project Costing

Profitability at a Glance: Your Complete Project Management Dashboard

DrawerCRUNCHER is more than just a cut list generator; it is a complete Project Management Dashboard. Instead of guessing your margins, you can instantly see the financial health of your project before you ever make the first cut.

- Automated Material Costing: Instantly calculate costs for both solid lumber (Board Feet) and sheet goods (Sheets) based on the specific dimensions of your drawer boxes and trays.

- Labor & Overhead Tracking: Factor in production labor by the hour or rate, alongside specific drawer expenses like slide hardware, specialty joinery time, and finishing.

- Precision Bidding: Use integrated metrics to ensure your quotes are consistent, competitive, and—most importantly—profitable.

- Accurate Lumber Ordering: Eliminate waste and "extra trips" to the lumberyard with calculated Lineal Footage and Rip Quantities based on your specific stock lengths.

- Total Project Transparency: See your total project cost at a glance, allowing for instant adjustments to labor rates or material choices to meet a client's budget without sacrificing your bottom line.

The 3-Step Guide to Profitable Quoting

One of the biggest challenges for small shops and DIYers is "hidden costs." DrawerCRUNCHER eliminates the guesswork by providing a real-time financial breakdown of your project, ensuring you account for every slide, screw, and board foot.

1. Automated Material Quantities

Stop manual board-foot calculations. Once your drawer or tray sizes are entered, the dashboard instantly provides:

- Material Requirements: Exact board footage for solid wood (e.g., Maple sides) and sheet material for the bottom panels.

- Specific Rip Lists: It tells you exactly how many lineal feet you need and how many physical boards (Rip Qty) to buy based on your standard stock length (e.g., 8-foot or 10-foot boards).

2. Comprehensive Labor & Overhead

A profitable job must account for your time and the hardware that goes into it. The dashboard allows you to:

- Calculate Labor: Enter your hourly rate and estimated build time to see a total production labor cost (e.g., 12 hours at $65/hr).

- Factor in Hardware & Extras: Easily add line items for drawer slides, pulls, finishing, and installation. Since drawer hardware is often a major expense, this ensures you never leave money on the table.

3. Real-Time Margin Analysis

Before you send the quote, verify your numbers with the Project Totals:

- Total Project Cost: See your bottom-line investment immediately (e.g., $845.50).

- Average Cost per Unit/Sq Ft: These powerful metrics allow you to see exactly what each drawer box costs to produce. Use this data to ensure your pricing is consistent, competitive, and—most importantly—profitable for your shop.

The DrawerCRUNCHER Profitability Checklist

One of the biggest challenges for small shops and DIYers is "hidden costs." DrawerCRUNCHER eliminates the guesswork by providing a real-time financial breakdown of your project.

1. Material Precision

- Verify Waste Percentage: Did you add a 10-15% buffer to the Board Footage to account for knots, grain matching, or shop errors?

- Sheet Good Yield: If the dashboard shows 1.1 sheets, ensure you have quoted for 2 full sheets, as most suppliers won't sell partial panels.

- Current Market Pricing: Check the Cost column against today’s lumber prices for your species (e.g., Cherry) to ensure your "Adjust Material Cost" is accurate.

2. Labor & Production

- Prep & Cleanup: Does your Production Labor quantity include time for setting up the router table, cleaning up glue squeeze-out, and final sanding?

- Finishing Time: If you are finishing the doors in-house, ensure the Finishing line item covers both the material (stain/topcoat) and the spray time.

3. The "Hidden" Costs

- Hardware Check: Did you include the cost of hinges, pulls, or drawer slides in the Hardware field?

- Delivery & Install: If you are doing the install, factor in travel time and site supplies (screws, bumpers, shims) under Installation.

4. Workflow Optimization

- Rip Quantity Check: Review the Rip Qty to see if you have enough physical boards on hand to complete all the stiles and rails in a single production run.

- Batching Strategy: Look at your Lineal Ft requirement; can you combine these cuts with another project to further reduce your waste?

5. Final Margin Audit

- The "Sanity Check": Compare your Average Cost per Sq Ft to your shop's standard minimum. If your calculated cost of $29.75 is lower than your target, adjust your labor rate or material markup accordingly.

Frequently Asked Questions

Please reach us at sales@cabinetcruncher.com if you cannot find an answer to your question.

DrawerCRUNCHER is bundled with DoorCRUNCHER into a single application called Door-DrawerCRUNCHER.

Door-DrawerCRUNCHER can be purchased as an individual program, or for those looking for a total shop solution, it is also included in our "All-In-One" Packages alongside CabinetCRUNCHER and CabinetVIEW (see Package 1 through Package 6). These packages are a popular choice for woodworkers who want to manage everything from cabinet carcass construction and 3D design to precision door and drawer production in one integrated software suite.

While they use the same intuitive interface and are bundled in the same application, DrawerCRUNCHER is specifically programmed with the logic needed for 5-piece box construction. It handles drawer-specific math like slide clearances and bottom panel "rattle room" that isn't required for door building.

Yes. You can toggle between Fractional (1/16"), Decimal, and Metric (millimeters) depending on your shop's preference.

This is a one-time purchase. There are no monthly fees or "cloud" subscriptions. You own a license to the software and can use it for as many projects as you like.

DrawerCRUNCHER is compatible with Microsoft Excel for both PC and Mac. It is also compatible with the free Excel app for iPad and Android tablets, making it easy to use right at your workbench.

Yes. To protect your profit margins, DrawerCRUNCHER includes a Precision Costing dashboard. It automatically calculates the Total Project Cost and the Average Cost per Sq Ft, allowing you to factor in material costs, labor rates, and overhead.

Yes. You can save significant time by copying your itemized drawer box lists directly from CabinetCRUNCHER into the DrawerCRUNCHER module. This seamless integration eliminates manual data entry and ensures that your project requirements flow perfectly from the cabinet design phase to the drawer production phase.

Yes. Much like the DoorCRUNCHER system, our unique "Drawer Group" functionality allows you to categorize your project into distinct sections. You can calculate high-end Through Dovetail drawers for main cabinetry in Group 1, Dado or Lock Joint rollout trays for pantries in Group 2, and specialized utility boxes in Group 3—all while the software consolidates the data into one master material and cost list.

Absolutely. The software allows you to define specific material thicknesses for every component. For example, you can set 1/2" Russian Birch for your drawer sides and backs while simultaneously specifying 1/4" Russian Birch for the bottom panels. DrawerCRUNCHER will then itemize these separately in your material list so you know exactly how many sheets of each thickness to order.

Yes. One of the tool's biggest strengths is its flexibility. You can enter the specific side and bottom clearance requirements for any slide brand or style, including side-mount ball-bearing slides and premium undermounts like Blum Tandem or Grass.

Absolutely. You can select from various joinery methods, including Through Dovetails, Half-Blind Dovetails, Dadoes, Rabbets, and Box Joints. The software automatically calculates the required offsets so your parts are cut to the perfect length for your specific joinery.

Yes. You can easily configure the settings for low-profile roll-out trays or "scooped" fronts. It is the perfect tool for outfitting a kitchen with custom internal storage.

The software utilizes a Bottom Panel Clearance setting. By entering your desired "Clearance space between dadoes," the program automatically adjusts the dimensions of the bottom panel so it is slightly smaller than the dado-to-dado opening. This prevents the panel from binding during assembly and allows for natural wood movement.

Not at all. If you can enter a measurement into a highlighted cell, you can use this software. It was designed by a woodworker for woodworkers, so it speaks your language—not "computer-speak."

Yes. If you decide to switch from 1/2" sides to 5/8" sides, simply update that setting in your Shop Standards. The entire project cut list and material cost summary will update instantly.

Copyright © 2026 CabinetCRUNCHER Cabinet Design & Construction Software. All Rights Reserved.